Search This Supplers Products:Tungsten sheets cruciblesTungsten platesMolybdenum sheetsMolybdenum platesTungsten heating elementsMolybdenum boats

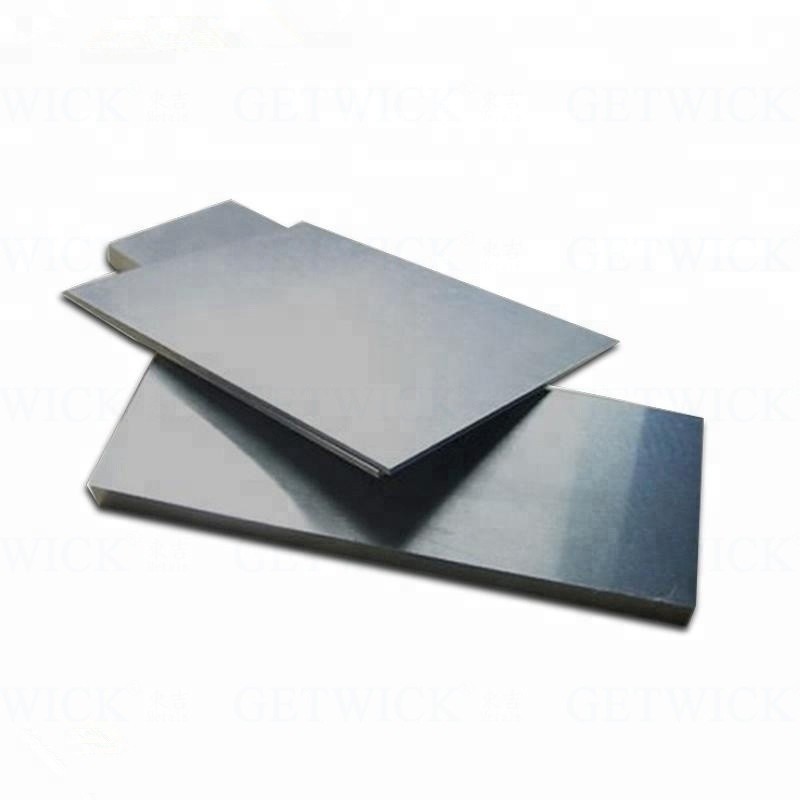

99.95% Pure Molybdenum Plate Mo for Vacuum Coating From GETWICK

- group name

- MOLYBDENUM PLATE

- Min Order

- 1 kilogram

- brand name

- GETWICK 東吉

- model

- 364, MLa

- Nearest port for product export

- Shanghai,, Guangzhou, Qingdao, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Mon, 08 Apr 2019 16:01:59 GMT

Paramtents

Key product High Density Buy Molybdenum Plate/Sheet

Material Molybdenum Lanthanated Alloy Sheet

Feature High temperature resistance

Application Vacuum furnace heatsheild

Standard ASTM B386

Grade 361, Mo1

Purity 99.95% Min

Working temperature 1700 - 1900

Advantage Factory supply price

Packging & Delivery

-

Min Order1 kilogram

Briefing

99.95% Pure Molybdenum Plate Mo for Vacuum Coating

Detailed

Product information

Item | pure moly sheet molybdenum metal plate suppliers and mu metal sheet |

Standard | ASTM B386, GB/T3876 |

Grade | Mo1, 361 |

Material | 99.95% min. Mo |

Density | 10.2g/cm3 |

Melting Point | 2610 Centigrade |

Using temperature | 1400 Centigrade max. |

Size | Thick 0.025mm min. x W600mm max. x L3000mm max. |

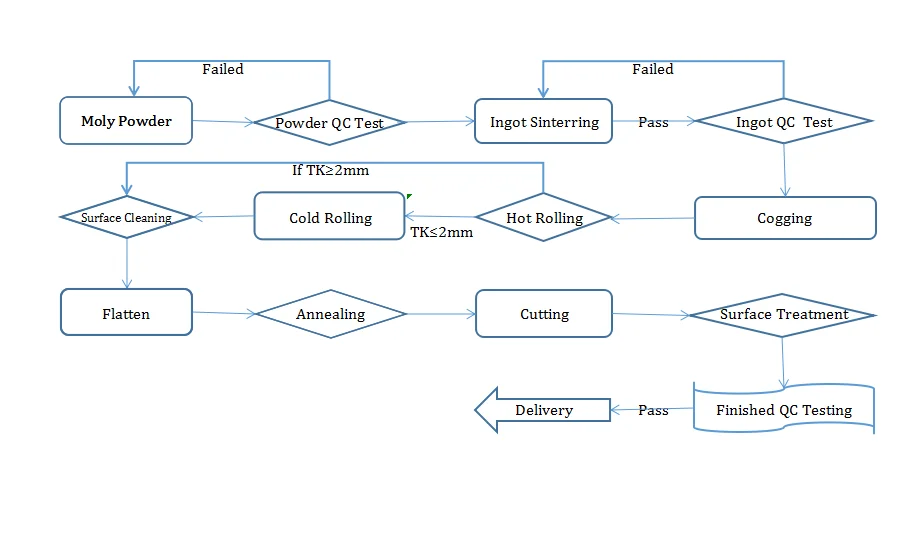

Processing | Cold rolled, Stress relief annealing, Hot rolled |

Colour | Black or bright |

Package | Standard wooden case as your request |

Feature

1. Low thermal expansivity

2. High using temperature

3. Good corrosion resistence

4. High strength

5. Low electrical resistivity

Surface:shiny, acid pickling, satin, or as-rolled condition; dependent upon thickness and width parameters.Normal condition: cold-rolled bright, acid pickling, polished.

Chemical requirements

Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Cd | Ca | P |

Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 |

Element | C | O | N | Sb | Sn | Mo |

|

|

| |

Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | balance |

|

|

| |

Normal specification we can provide:

Molybdenum Plate/Sheet /Foil/Strip | ||

Thickness(min) mm | Width(max) mm | Length(max) mm |

0.025~0.09 | 150 | 1000 |

0.1 | 350 | 1500 |

0.12 | 400 | 1500 |

0.15 | 420 | 1500 |

0.2 | 450 | 2000 |

0.3~1 | 550 | 2500 |

1.5~5 | 500 | 2000 |

5~25 | 500 | 1500 |

Tolerance Chart(mm) | |||||

Thickness | Width | Length | |||

Range | Tolerance | Range | Tolerance | Range | Tolerance |

0.1~0.15 | +/-0.1 | 50~200 | +/-1 | 100~1500 | +/-3 |

0.15~0.30 | +/-0.02 | 50~200 | +/-1 | 100~1500 | +/-3 |

0.3~0.5 | +/-0.03 | 50~200 | +/-1 | 100~1800 | +/-3 |

0.5~0.7 | +/-0.04 | 50~500 | +/-2 | 100~2000 | +/-3 |

0.7~1 | +/-0.05 | 50~600 | +/-2 | 50~2000 | +/-3 |

1.0~2.0 | +/-0.05 | 50~600 | +/-2 | 50~2000 | +/-4 |

2.0~3.0 | +/-0.05 | 50~550 | +/-2 | 50~1500 | +/-5 |

3.0~4.0 | +/-0.1 | 50~550 | +/-3 | 100~1500 | +/-5 |

4.0~5.0 | +/-0.1 | 50~550 | +/-3 | 100~1500 | +/-5 |

Application

1.Used for producing molybdenum targets, boats, discs, etc.

2. Used as protection cover in glass coating industry

3. Used for the electronics industries, such as intergrated circuit, information storage, LCD, laser storage, electronic control device, etc.

4. Mainly used as heat shield and reflection shield in high temperature furnace industry, such as vacuum furnace, sapphire growing furnace, etc.