Search This Supplers Products:Tungsten sheets cruciblesTungsten platesMolybdenum sheetsMolybdenum platesTungsten heating elementsMolybdenum boats

99.95% MO1 molybdenum crucible

- group name

- MOLYBDENU7M CRUCIBLE

- Min Order

- 1 set

- brand name

- GETWICK 東吉

- model

- Mo1

- Nearest port for product export

- Shanghai,, Guangzhou, Qingdao, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Thu, 18 Apr 2019 15:00:05 GMT

Paramtents

Key product 99.95% MO1 molybdenum crucible

Grade Mo1,TZM, MLa

Working temperature 1300-2000 Centigrade

Purity 99.95% Min

Density 10.2g/cm3

Material Pure Molybdenum

Dimension User's demand

Processing Forged or Sintered

Feature High Temperature Resistance

Application Melting

Packging & Delivery

-

Min Order1 set

Briefing

Competitive price, good quality

for melting industry

Detailed

99.95% MO1 molybdenum crucible

Molybdenum Crucible Introduction:

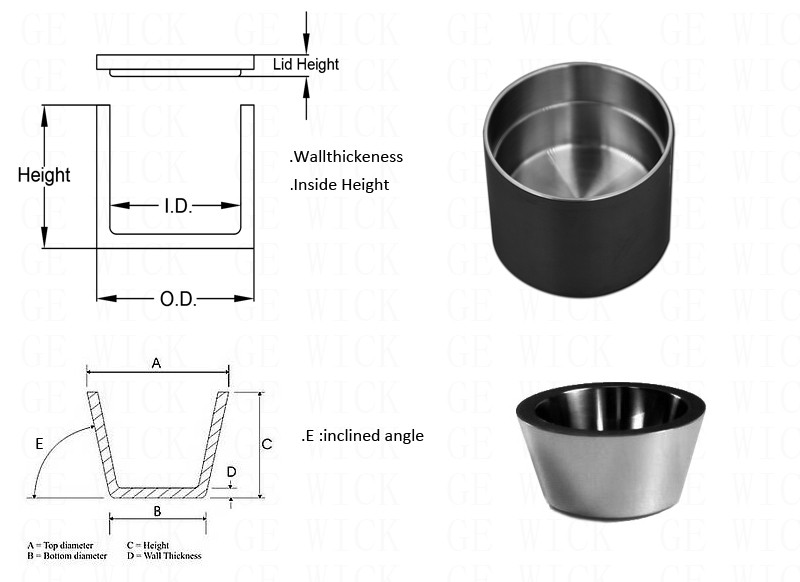

Molybdenum crucibles can be produced with sintering purposes (density of 9.8-10g/cc) or forging purposes (up to 10.2g/cc). Customized shapes for Molybdenum crucibles include, but are not limited to, oval, tapered, bottomless, or round mouth.

Molybdenum Crucibles can be used in LED Sapphire Crystal Growing and Chemical industry. GETWICK can provide customized molybdenum crucibles according to customer's drawings. We can also provide solutions for your research. GETWICK has a vertically integrated supply chain with the capability to refine molybdenum powder, press and sinter ingots, roll input material for spinning, spinning to form, trim, and clean molybdenum and molybdenum alloy crucibles. GETWICK can manufacture a wide-range of diameter, height and thickness crucible sizes to suit our customers' needs.

Poduct Name | Pure 99.95 molybdenum crucible for melting |

Brand | GETWICK |

Origin | Baoji, Shaanxi,China |

Usage Temperature | 1300-1400Centigrade:Mo1 2000 Centigrade:TZM |

Size | OEM drawing Customized size |

Grade | Mo1,TZM, MLa |

Surface | Finish turning, Grinding |

MOQ | 1pc |

Delivery time | 12-15 workdays |

Market | Global |

Condition | 1.Molybdenum rod or ingot |

Forge molybdenum crucible | |||||||

Purity | Density | Sizes | Tolerance | Wall thickness | roughness | ||

99.95% | ≥10.1g/ cm3 | Dia(mm): | Height(mm): | Dia: | Height: | 4-20mm | Ra=1.6mic |

Sinter molybdenum crucible | |||||||

Purity | Density | Sizes | Tolerance | Wall thickness | roughness | ||

99.95% | ≥9.8g/ cm3 | Dia(mm): | Height(mm): | Dia: | Height: | 8-20mm | Ra=1.6mic |

Feature

1. Low thermal expansivity

2. High using temperature

3. Good corrosion resistence

4. High strength

5. Low electrical resistivity

6. Manufacturing based on customer’s request

Application

1.Widely used in melting metals, such as steel, aluminum, etc.

2.Widely applied in high temperature vacuum furnace melting environment such as sapphire growing furnace, quartz glass melting furnace, and rare earth melting furnace.

3.Also used in industries as following:

Ceramics, metallurgical, machinery processing and light industry.