Search This Supplers Products:Tungsten sheets cruciblesTungsten platesMolybdenum sheetsMolybdenum platesTungsten heating elementsMolybdenum boats

Why Tungsten and Molybdenum Add Strength in Manufacturing

time2018/12/27

Why Tungsten and Molybdenum Add Strength in Manufacturing

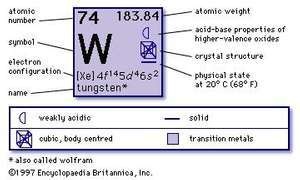

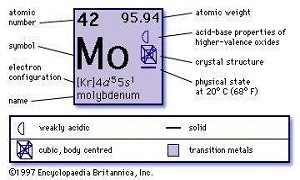

Tungsten and molybdenum manufacturing methods have both followed similar historical paths in development. Both elements were first isolated in their pure forms toward the end of the 18th century. Tungsten was given its name by Swedish Chemists and it means “hard Stone” It is also known as Wolfram. It was not until the 20th century that the full use of molybdenum and tungsten products were fully utilized.

Neither tungsten or molybdenum are not found naturally. Tungsten has to be separated from one of the mineral elements (iron, manganese, and calcium) in which it is combined in its natural state. Molybdenum has to be separated from molybdenite or found as a trace element in copper. After separation, Tungsten and molybdenum are compressed into metallic powders at a very high pressure. Then they are most often used to make alloys. They are used to increase strength, hardness, electrical conductivity and resistance to corrosion and wear.

For example, molybdenum is used as glass electrodes in glass furnaces as electrodes because of the resistance to degradation and glass discoloration. Because Molybdenum has similar durability, but less density,molybdenum boats are produced for their reliability. Because of tungsten conductivity, it is widely used as a filament in lights, as well as drilling and boring equipment. Tungsten crucibles are highly valued because of their extraordinarily melting point. Tungsten’s ability to retain conductivity at high temperatures and while maintaining its other physical characteristics even at extreme temperatures make it ideal for tooling applications, x-ray and radiation therapy equipment among many other uses.