Search This Supplers Products:Tungsten sheets cruciblesTungsten platesMolybdenum sheetsMolybdenum platesTungsten heating elementsMolybdenum boats

How Does Molybdenum Alloy Form

time2018/10/08

How Does Molybdenum Alloy Form

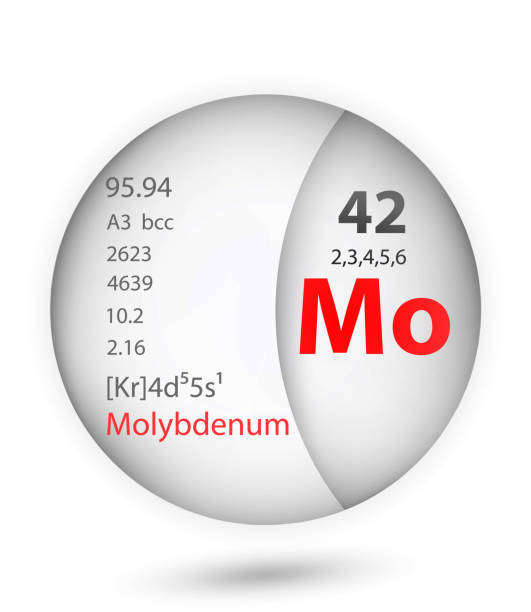

Due to its unique mechanical and chemical properties, molybdenum has become an

outstanding material capable of meeting the most demanding requirements. Its advantages are its extremely high melting point, low coefficient of thermal expansion and good thermal conductivity, so it is widely used in many different industrial fields. Its wide range of applications include: industrial tapes for lighting and filaments, semiconductor substrates for power and electronics industry, glass melt electrodes and hot zones for high temperature furnaces, and sputtering target for solar cell and flat panel displays.

Molybdenum alloy is mainly TZM, ML alloy.

TZM (Titanium Zirconium Molybdenum)

Molybdenum metal is transformed into TZM alloy using a small amount of ultra-fine micro carbides. TZM alloys are not only harder than pure molybdenum but also have higher recrystallization temperatures and better creep resistance. TZM can be used in high temperature applications where harsh mechanical loads exist, such as in knife forging or X-ray tube rotating anodes. TZM's recommended operating temperature is 700℃ to 1400℃.

ML (Molybdenum Lanthanum oxide)

The mixture of molybdenum with a small amount of lanthanum oxide particles (0.3% or 0.7%) can form the so-called laminated fiber structure. This special microstructure can also be stable at temperatures of up to 2000°C. Therefore, even in extreme conditions of use, molybdenum-lanthanum oxide is also creep resistant. We mainly process such alloys into high temperature furnace components, such as strands and other metal wires, sinter and anneal boats, or evaporator coils.

In the lighting industry, lanthanum molybdenum oxide is also used as a guard wire and feeder.