Search This Supplers Products:Tungsten sheets cruciblesTungsten platesMolybdenum sheetsMolybdenum platesTungsten heating elementsMolybdenum boats

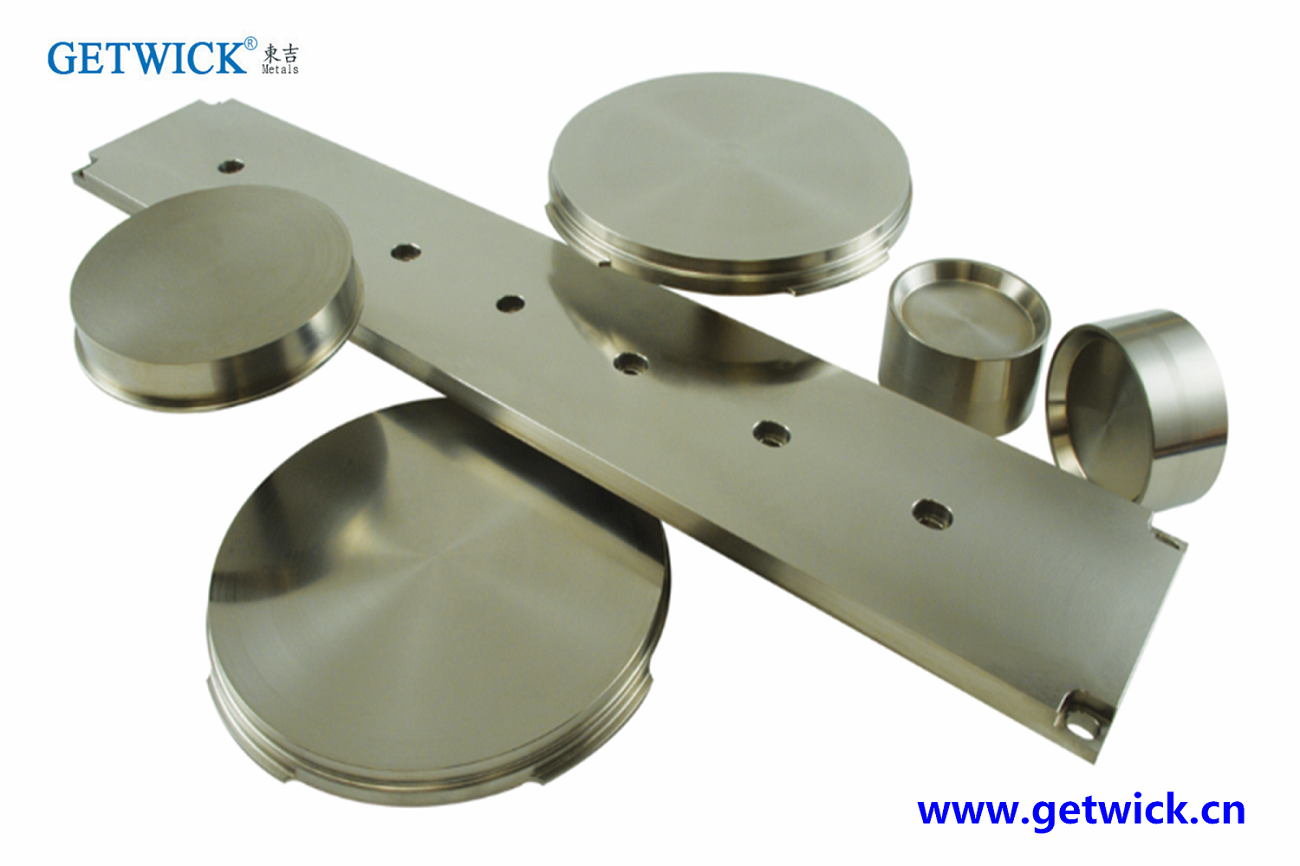

How Do Sputtering Targets Work?

time2018/08/31

- Sputtering targets are components of the thin-film transistors used in TFT-LCD screens. They are used wherever large screen formats, particularly high image definition and optimized contrasts are needed

What Is Sputtering?

It's an electronic process that deposits thin films of metals or other materials onto a variety of surfaces. Most often, sputtering is used to apply thin platings onto silicon wafers, solar panels and display screens.

How Does Sputtering Work?

Sputtering is done in a vacuum chamber into which an inert gas is introduced – in most cases, argon. Two items are placed into that chamber: the item to be plated, and the “target” that contains the material that will be applied. A negative electrical charge is applied to the target, causing some of the electrons that it contains to travel to the material to be coated. Presto! You’ve got a thin film of plating right where you want it. But note that the use of the term “target” can be confusing, since it is the source of the plating material that is used, not its final destination.

What Metals or Other Substances Can Be Delivered from Sputtering Targets?

Sputtering targets are now being used in a many industries for the first time. As a result, targets are being used to apply molybdenum, tungsten,zirconium,chromium,tantalum,niobium and even more materials that can be used as coatings or platings.

How Much are Used Sputtering Targets Worth?

That can vary, depending on the value of the metal that you are using as platings, the presence of secondary metals in the sputtering targets that you use, the strength and efficiency of your sputtering applications, and more. The one way to be sure is to send your used sputtering targets to a qualified precious metals recycler for testing.