Search This Supplers Products:Tungsten sheets cruciblesTungsten platesMolybdenum sheetsMolybdenum platesTungsten heating elementsMolybdenum boats

On the Recrystallization Behavior of Technically Pure Molybdenum

time2018/08/28

On the Recrystallization Behavior of Technically Pure Molybdenum

In the last decades the amount of interstitial impurities in the raw material used for powder metallurgical production of Molybdenum has been reduced significantly. For processing pure Molybdenum and

the resulting mechanical properties, the recrystallization behavior, The recrystallization behavior has been monitored on differently deformed and subsequently heat-treated samples by means of hardness testing, light-optical microscopy and scanning electron microscopy employing electron channeling contrast imaging . Thus, the recrystallization behavior is strongly dominated by concurrent recovery processes,which deviate from that of fcc metals showing a comparably low stacking fault energy. Finally, the revised recrystallization diagram for technically pure powder metallurgically processed Molybdenum is presented.

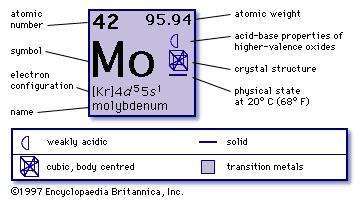

Pure Molybdenum possesses a unique combination of physical properties including excellent hightemperature strength, high corrosion resistance except oxidation resistance, high thermal conductivity, a high elastic modulus and a low thermal-expansion coefficient. Because of these outstanding properties,technically pure Molybdenum is used in a wide range of applications, including lighting-technology, highPrimig,Highly deformed Molybdenum is ductile at roomtemperature,but recrystallization leads to room-temperature embrittlement, which is not an intrinsic property of Molybdenum itself, but is caused by the presence of interstitial impurities. Because of its high melting point (2620°C), Molybdenum is nowadays mostly produced by powder metallurgical procedures. During the last decades, the amount of these interstitial impurities in the raw material has been reduced significantly. At the same time, the properties of technically pure Molybdenum have changed by adapting the PM production process to the latest technological standards. The recrystallization behavior of Molybdenum, which is strongly influenced by the process parameters of the thermo-mechanical treatment and the purity of the material, is decisive for the resulting mechanical properties, for example ductility, hardness, strength and toughness.Therefore, a recrystallization diagram is essential for the prediction of the recrystallized grain size and to gain knowledge about how the recrystallization temperature depends on the degree of deformation.

The findings of the present study are discussed in comparison with Pink’s recrystallization diagram.