Search This Supplers Products:Tungsten sheets cruciblesTungsten platesMolybdenum sheetsMolybdenum platesTungsten heating elementsMolybdenum boats

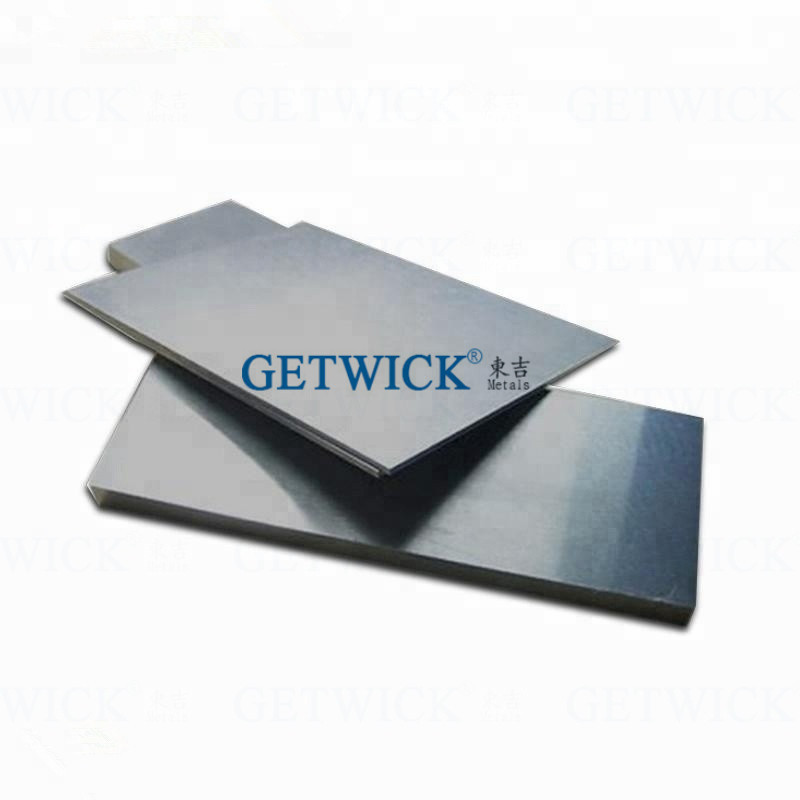

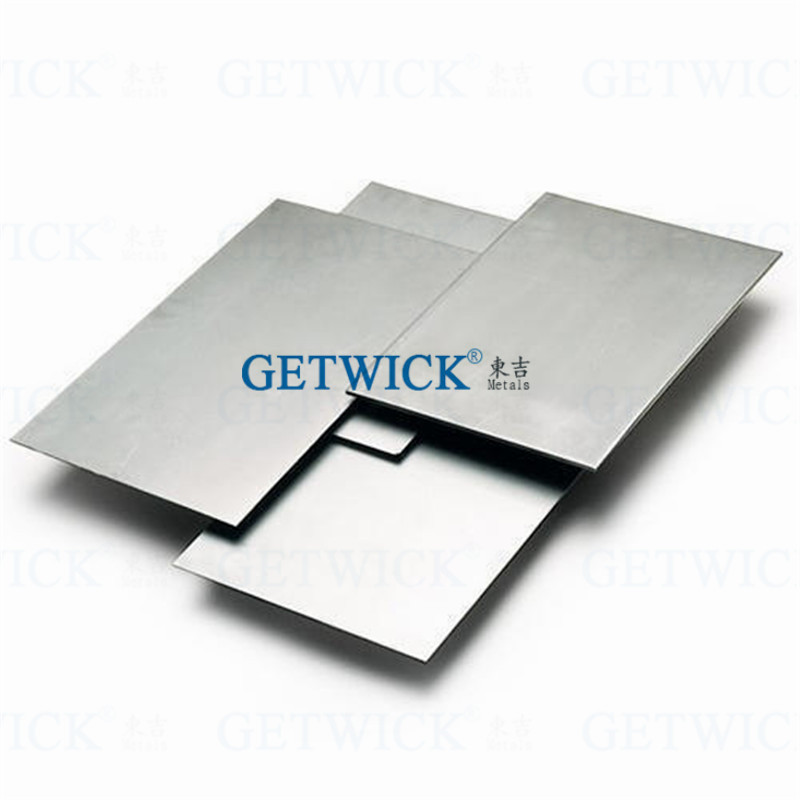

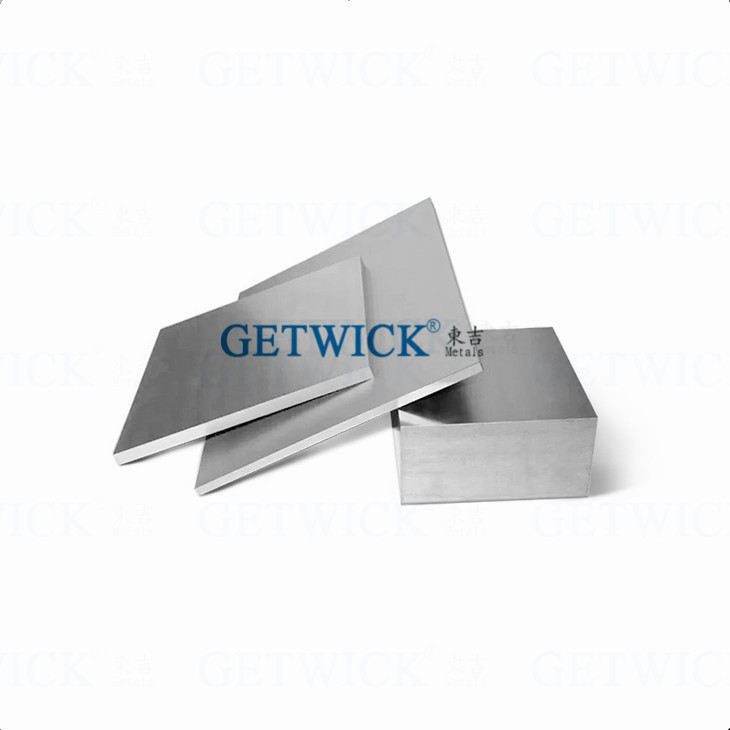

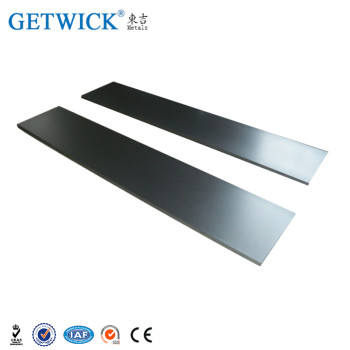

Buy TZM Molybdenum Sheet Plate for Heat Shield

- group name

- TZM PLATE

- Min Order

- 1 kilogram

- brand name

- GETWICK 東吉

- model

- TZM, 364

- Nearest port for product export

- Shanghai,, Guangzhou, Qingdao, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Wed, 10 Apr 2019 13:22:44 GMT

Paramtents

Key product Buy TZM Molybdenum Sheet Plate for Heat Shield

Standard ASTM B386

Grade 364, TZM

Material Ti, Zr, Mo alloy

Melting point 2610 Centigrade

Working temperature 2000 Centigrade max.

Size Thick 0.1mm min. x W680mm max. x L3000mm max.

Feature High temperature resistance

Advantage Factory Direct Supply TZM Molybdenum Sheet Plate

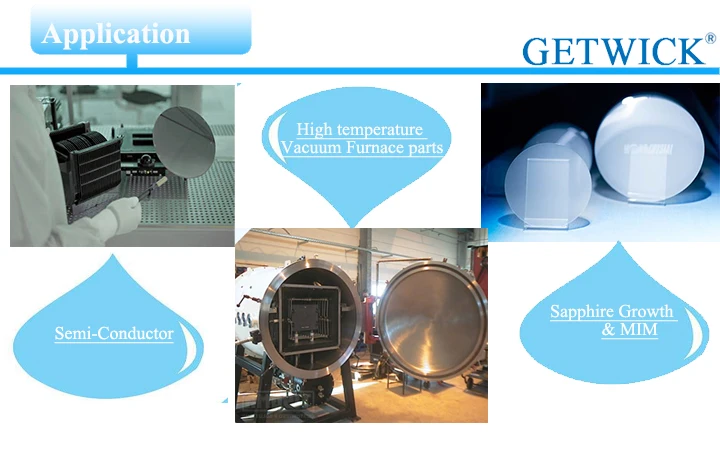

Application Vacuum furnace heatsheild

Packging & Delivery

-

Min Order1 kilogram

Briefing

Buy TZM Molybdenum Sheet Plate for Heat Shield

ASTM B386 standard followed, 2000 Centigrade using point

Factory supply

ASTM B386 standard followed, 2000 Centigrade using point

Factory supply

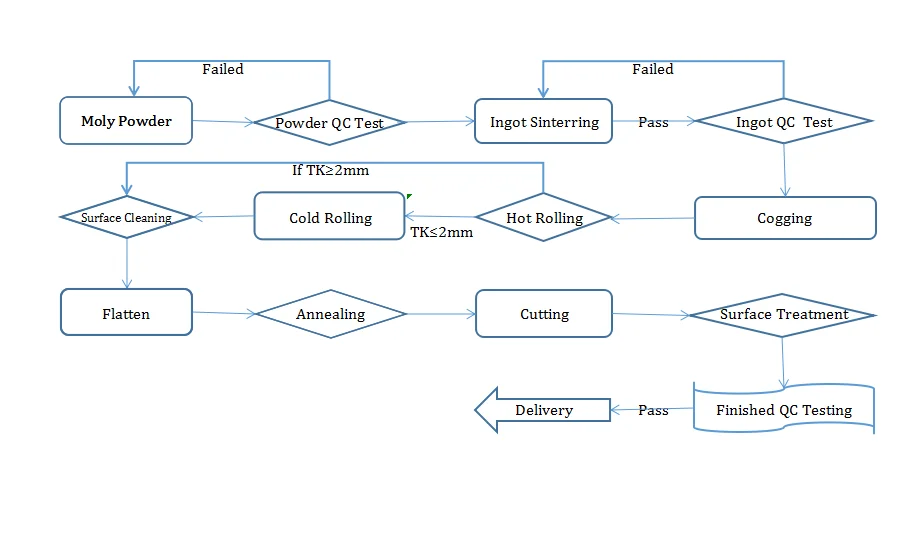

Detailed